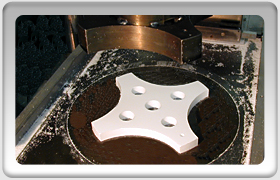

Multi-Cavity Tool

Multi-Cavity Tool

Molded PTFE parts

Molded PTFE parts

ready to sinter

| |

APT's dependable Teflon® PTFE compression molding presses were custom designed for the particular molding characteristics of PTFE resins. Our presses produce high quality preforms that yield finished parts with consistent mechanical properties throughout the material lot.

Our automatic PTFE compression molding equipment, with operational ranges from 10 to 300 tons of pressure, provides us with the capability to mold parts from 1/16” thick to *36” long (*utilizing a modified PTFE fusion technique).

APT's PTFE compression molding tooling is custom designed in-house. Higher volume molding projects leverage cost savings obtained through the use of molded nearnet shapes. Nearnet shapes minimize the amount of excess material required to obtain

a finished piece and subsequently reduce machining time. Time & material savings are ultimately compared to the initial cost of tooling to determine a volume level that supports a custom tool.

APT's PTFE (polytetrafluoroethylene) molding processes include:

- PTFE Automatic Compression Molding:

Material Blanks & Dimensionally

Finished

“As Molded” Parts

- Multi-Cavity Tools for increased molding efficiency

- Modified PTFE Fusion Fabrication (Note: This process is different from hot gas welding)

APT's modified PTFE fusion process is best applied to cylindrical forms such as the special cylinders and containers shown below.

Above (L to R): Modified PTFE Hollow Cylinders with tapered plug; Modified PTFE Container with thermally conductive bottom; Modified PTFE Container - 21 Liter.

Above: PCTFE machined parts and molded stock blanks.

PCTFE (Polychlorotrifluoroethylene) is a high performance thermoplastic with unique properties that include rigidity, toughness, cold flow and stress crack resistant. Suitable as a valve component material for cyrogenic fluid service. PCTFE maintains its properties over a wide thermal range.

Call us today to discuss your custom application.

|